Quality and Customer Trust

Improving Quality

Basic Approach

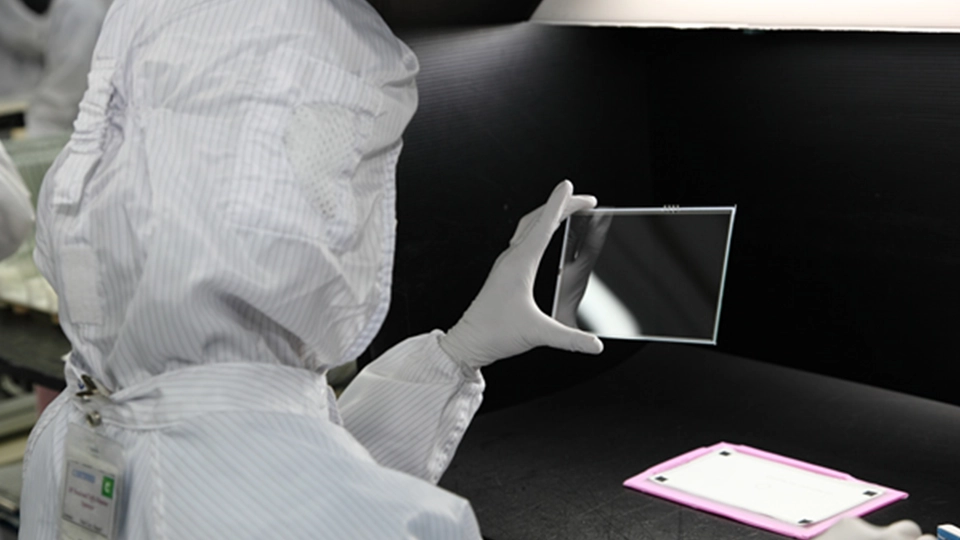

SMK upholds Ultimate Quality Management as a core belief. This involves not only employees in divisions directly engaged in production, but all departments across the company.

TN Quality Improvement Committee

SMK holds The TN Quality Improvement Committee as a forum to report the quality status of the entire company to executive management and share information with the heads of production sites and quality assurance managers. When a serious complaint occurs, a detailed report covering aspects from the cause of the complaint to the prevention of its recurrence is made and guidance on countermeasures is provided at the committee meeting. Even for minor quality issues, we are strengthening reporting and information-sharing to prevent recurrence and proactively avoid problems.

Quality Assurance System

SMK has built an end-to-end quality assurance system based on the international standard ISO 9001. In addition, we have obtained IATF 16949, the international standard for automotive industry quality management, at six sites. For a list of certified sites, please see the Certifications page.

Quality Goals

SMK aims to achieve "ZD (Zero Defects)". We believe that product quality is ensured only when each department—from sales to R&D, design, production, inspection, shipping, and delivery—improves and fulfills its own responsibilities with high standards.

In particular, we focus on establishing a front-loading approach that eliminates potential manufacturing issues at the early stages of product development, to minimize rework later, as well as ensuring the thorough implementation of Design Reviews (DR).

As a result of these efforts, the number of customer complaints has been decreasing year by year.

Company-Wide Quality Improvement Activities

SMK designates October to December each year as SMK Quality Month. As the main event, we hold the TN Q-Up Conference across the SMK Group. Representative teams that won at QC Circle* Meetings held at each production site take part in this event. The presenting teams share the results of various improvement activities, including productivity and yield improvements.

We will continue to promote group-wide initiatives by enhancing QC Circle activities—the foundation of our quality improvement efforts—to encourage both self- and mutual development among employees.

- *

Small groups where workplace employees continuously manage and improve the quality of products, services, and work

Quality Improvement Through Collaboration with Suppliers

To provide products with stable quality, SMK conducts quality audits of suppliers and holds regular Quality Meetings with them. At these meetings, we share quality performance reports, improvement cases, notifications, and provide education, while engaging in active discussions to resolve issues. Through these initiatives, we strengthen trust with our suppliers and strive to ensure even higher quality standards.

Improving Customer Satisfaction

Basic Approach

SMK seeks to be useful to society and upholds as the first principle of the SMK Group Charter for Corporate Behavior "For customer confidence, we will develop and provide superior goods in terms of quality, cost, and safety through our accumulated advanced technology." We believe that customer satisfaction is the most important element in determining SMK's significance and value as a company. Therefore, all departments including sales, design, production, quality control, and manufacturing sites work together to improve customer satisfaction.

Customer Satisfaction (CS) Surveys

SMK conducts CS questionnaires every year, targeting customers in material procurement, technology, and quality departments to survey how customers perceive not only product quality but also SMK's activities and improvement efforts.

CS survey results are fed back to the entire company and reflected in improvement initiatives, primarily in the product divisions and the production, technology, and quality departments. In addition, for problems discovered through the survey, we analyze causes and create specific solutions to address them.

| FY2021 | FY2024 | |

|---|---|---|

| Overall score 4-point scale from 1 (satisfied) to 4 (dissatisfied) | 1.77 | 1.65 |

| Data coverage (%) Sales from customers surveyed / Net Sales × 100 | 57 | 25 |