ご使用上の注意(スイッチ)

必ずお読み下さい

-

(1)

本カタログに掲載している製品は、携帯電話、PC、家電製品、デジタルスチルカメラなどの電子機器用に設計・製造されたものです。

-

(2)

医療用生命維持装置、宇宙・航空機器、防災・防犯機器等の高い安全性や信頼性が求められる用途に使用される場合は、保護回路や冗長回路を設けるなど機器の安全性を図ると共に、当該製品の適合性を十分確認の上、ご判断ください。スイッチの品質については万全をつくしておりますが、故障モードとして接触抵抗値変化(増大)、ショート、オープン、温度上昇などの発生が皆無とはいえません。万が一スイッチが故障しても機器の安全性が保たれるよう機器設計時フェールセイフ設計などの安全性にご配慮をお願いいたします。

-

(3)

一般スイッチは密閉・防水構造にはなっていませんので、洗浄できません。水のかかる環境及びはんだ付け後プリント配線板を洗浄する条件でご使用する場合は、防水タイプまたは洗浄タイプをご指定ください。

-

(4)

一般スイッチは密閉構造になっていませんので、塵埃が多い環境でご使用する場合は、防塵タイプをご指定ください。

-

(5)

スイッチ接点は、一般的に銀又は銀めっきが採用されています。銀及び銀めっきは硫化ガスによる硫化皮膜が形成されやすい性質をもっており、硫化皮膜が形成されると接触障害が発生します。次の様な環境及び条件で使用する場合は、事前に当社にお問い合わせの上、金めっき及び密閉タイプのスイッチなどの対策品を使用してください。

-

①

硫黄系温泉地などの常時硫化ガスが発生している環境

-

②

車などの排気ガスの発生する場所で常時使用する場合

-

③

スイッチの切換頻度が非常に少なく(1回/1年など)、負荷電流が1mA以下の微小電流で使用され、接点の信頼性が高く要求される場合……半固定スイッチ、回路チェック用スイッチなど

-

※

スイッチの接点は、切換が行われることによって接点表面が摺られ新しい面による接触安定が保たれる構造のものが多く、切換頻度が少ない場合、OFF側接点に硫化皮膜などが形成されやすく接触が安定するには2〜3回の切換が必要となる場合があります。また、この様な使用条件下ではめっきの種類に関わらず、ご使用条件で接触障害及び動作不良となる恐れがありますので、当社にお問い合わせください。

-

-

-

(6)

保管は、開梱せずに常温・常湿で保管してください。一度梱包を開封したものは、適切な防湿・防ガスなどの処置をし、ポリ袋に入れ密閉するなどの上保管して下さい。スイッチは、納入後常温常湿の環境下で保管し、6ヶ月を限度にして使用してください。6ヶ月以上経過したものは、はんだ付け性及び電気的性能(特に接触抵抗)をチェックの上使用して下さい。スイッチは保管環境によっては、銀めっき端子の硫化、酸化によるはんだ付け性が劣化する恐れがあります。長期在庫が必要となる場合は、端子表面の被膜生成によるはんだ付け性劣化などを防ぐため、スイッチをポリ袋などに入れて密封し、直射日光の当たらない冷暗所に保管してください。

-

(7)

テーピング梱包品の保存温度範囲は−20℃〜+50℃です。

-

(8)

マイクロアンペアの微小電流でご使用される場合、実機での動作確認を行い、使用可否のご判断をお願いします。

-

(9)

スイッチに規定以上の荷重が加わると破損する場合があります。スイッチ本体に規定以上の荷重が加わらないようにご使用ください。規定荷重については当社までお問い合わせください。

-

(10)

スイッチの復帰力で、他の機構を復帰させるような使用方法は避けてください。

-

(11)

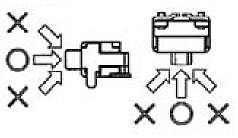

一般スイッチは垂直に真っ直ぐ押し込むようにご使用ください。斜め押しをする使用方法は避けてください。

-

※

参考例

-

-

(12)

スイッチのはんだ付け作業は、必ず当該製品のはんだ条件の記載した条件に従い、実際に使用する装置、基板で確認を行ってください。

-

(13)

リフローはんだの場合、リフロー槽の種類、基板の材質・厚さ、部品の位置などにより条件の異なることもありますので、事前に適切な条件を確認のうえでご使用ください。

-

(14)

はんだ付けの際、水溶性フラックスはスイッチを腐食させる恐れがありますのでご使用はお避けください。

-

(15)

本カタログでは寸法、仕様書は主要なものに限って記載しております。詳細については図面、仕様書をご請求の上ご確認ください。また、ご使用に際しては正式納入仕様書の取り交わしをお願いします。

-

(16)

品質向上、製品改良などにより、仕様書を予告なく変更させていただく場合があります。

-

(17)

本カタログの記載製品の詳細については当社までお問い合わせください。

以上